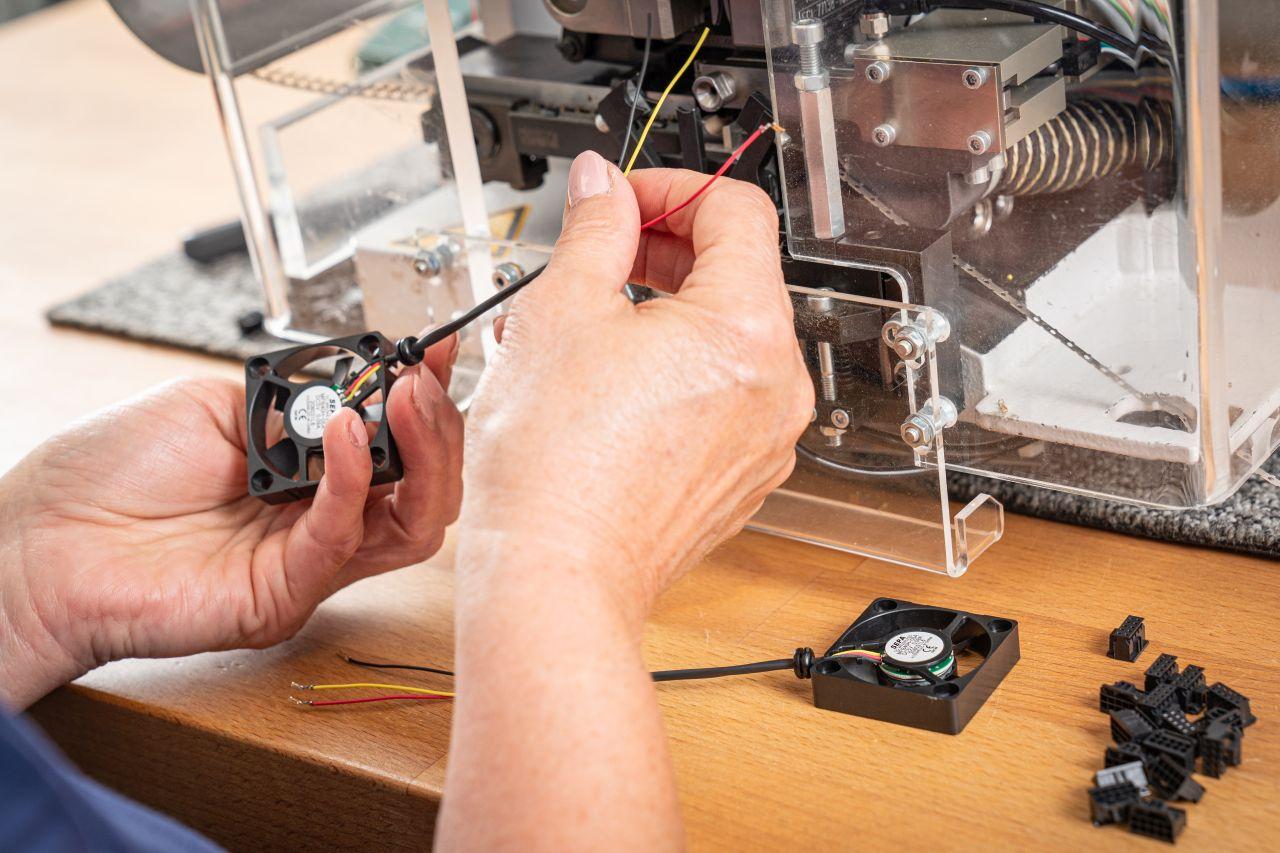

Customer-specific cable assembly

SEPA EUROPE is the right partner for fulfilling your requirements as far as cable assembly is concerned. Thanks to our long years of experience we are in a position to give you the necessary support during the entire development stage and can address your specific needs by offering our sophisticated services quickly and cost-effectively. Fans that require assembled connectors are usually available at short notice.

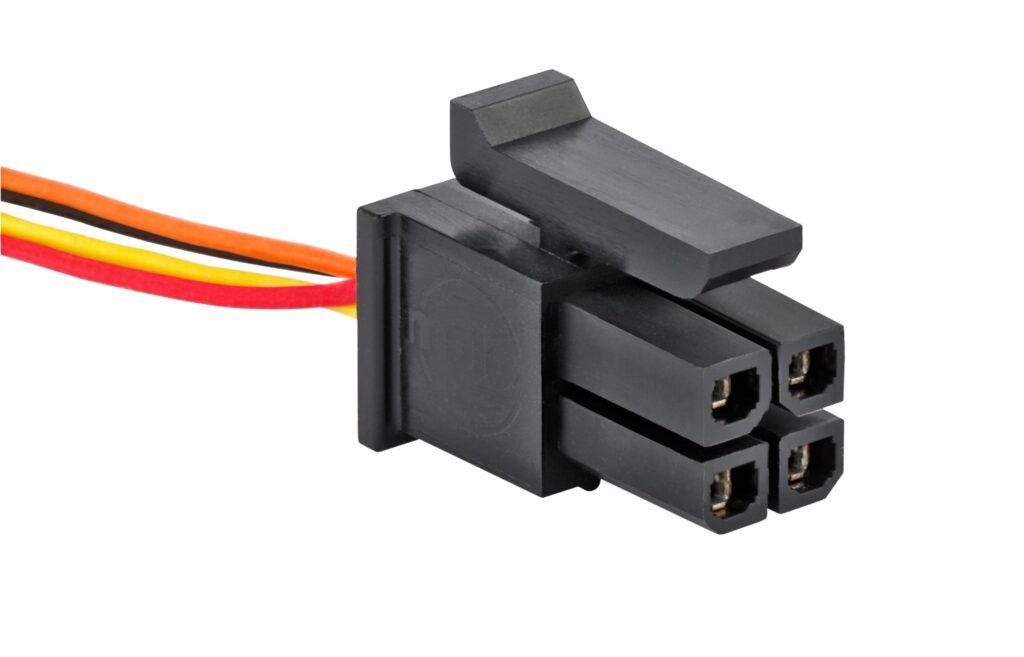

Regardless of the type of connector you require for your fan, we have a wide selection on offer. Whether large or small series assembly, single board connector, special design with individual label, PVC or shrink hose, protective hose, labels or markings, or various wire lengths and pin assignments, we are familiar with all these requirements and are thus in a position to complete orders ready for connection as required by the individual customer. This applies even when it’s urgent.

Your advantages

- Quick and flexible design

- Extensive range of connectors

- Consistent quality and design (see sample)

- Documented tensile testing

- 100% electrical test for continuity and short circuit

- Cable assembly with original connectors of renowned manufacturers (e.g. Molex, JST)

- Approval samples for customers

- Customer-specific small series/pre-assembled connectors available for orders of just 1 item

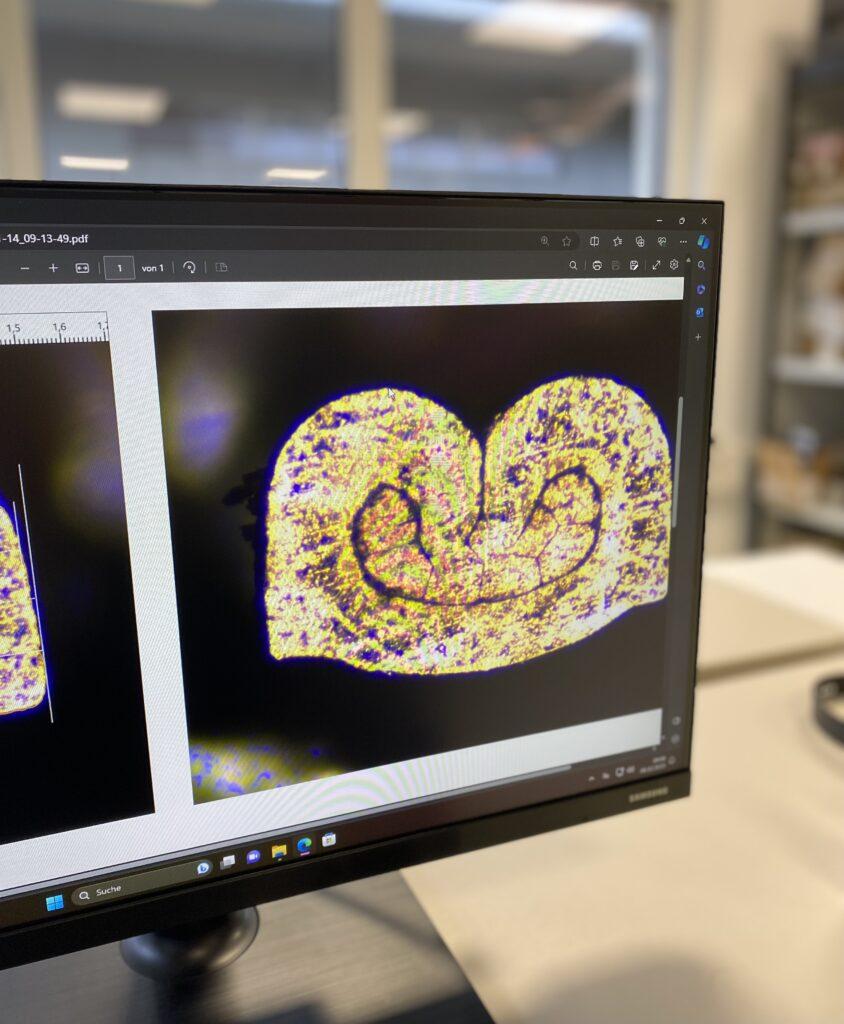

Quality assurance by means of micrograph analysis

Quality assurance presents a constant challenge. Standard processes such as the measurement of the crimp height and pull-off force are a well established factor in quality control and have stood the test of time. Conventional measurement methods can however reach their limits when confronted with wear and in particular change of tools or material.

However, as our aim is to deliver first-class products at all times, we have acquired a new technological highlight – micrograph analysis. The precise analysis of the cross-sections of crimp samples enables the detection of quality defects that are not identified by other methods. Through micrograph analysis we can ensure that every part that leaves our premises meets our quality standard.