No chance for hot spots!

Technical infos

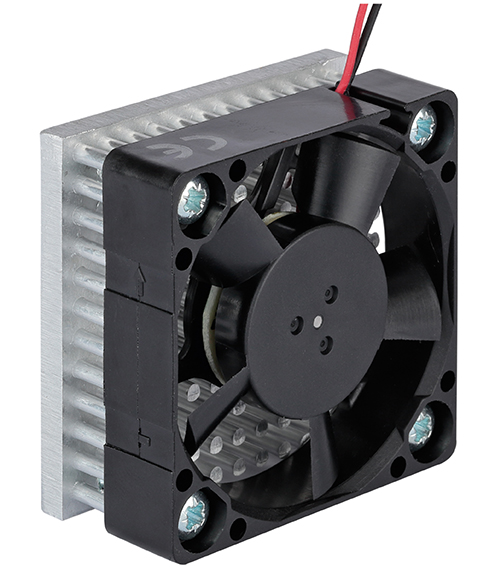

In comparison to active (HXB50E05) and passive heat sinks with identical thermal resistance however the heat sink has 5x the volume and weight compared to HXB50E05.

Whereas the use of fans for control cabinet cooling is a matter of course and standard fans are widely employed for this purpose, the active cooling of small devices is far more complex. As many problems and the requests of our customers with regard to design, technical and optical details must often be given consideration, their use cannot be limited to just a few standard sizes.

Over the last years, SEPA EUROPE has increased its range for the cooling of

electronic components in embedded systems. Environmental requirements were also taken into account as it was possible not only to significantly reduce the power

consumption with equivalent or improved effect but also to decisively reduce the use of raw materials. As far as small devices are concerned, the problem is usually not the dissipation of heat generated by all components but the cooling of the „hot spots“.

Passive cooling requires approx. 5 times more heat sink volume than cooling supported by a fan and can hardly be accommodated in the space that is available for this purpose. Thanks to modern active cooling, the devices can be smaller, lighter and cheaper without experiencing quality cutbacks.

This is possible due to the creation of a number of new, modified axial, radial and

RaAxial fans and new specially designed heat sinks and accessories. In the meantime many of these new components have become standardized and are available from stock but experience shows that

customized versions are often unavoidable.