5 tips on how to find the right fan!

5 tips on how to find the

right fan

All electronic components heat up during operation. Excessive temperatures can however change the properties of the components or even destroy them. If this is no option for you, the following useful tips will help you to find a suitable thermal management and protect the service life of your entire system.

How efficient must the fan be?

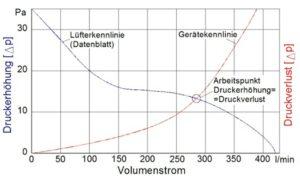

Fans are used for circulating air and pressing it through a unit for example electronic equipment. The unit counteracts this by flow resistance. The fan overcomes this resistance by creating pressure. The higher the volume flow rate created by the fan through the device, the higher is the flow resistance (pressure loss) that the fan has to compensate for due to the higher pressure. The consequence is a state of equilibrium between the fan and the device.

The output specified in the data sheets is based on a free-blowing fan without counterpressure where the fan provides the maximum volume flow rate. Should the fan however blow the air into a space without an air outlet, it develops its maximum pressure at a volume flow rate of 0. This value is also specified in the data sheets. The curve between these two extreme values shows the relationship between output and pressure. If the fan is connected to a device it must overcome the flow resistance by building up a certain amount of pressure whereby the volume flow rate is reduced. The device curve shows the pressure loss in relationship to the volume air flow. The intersection of the fan and the device curve is the operating point of the fan.

In order to determine the fan curve, elaborate test systems are required which only the fan manufacturers possess. Users and distributors usually do not have these systems. The required output can be determined by simulation programs always assuming that the device geometry and fan curve is precisely known and stored in the simulation program. The empirical method is simpler and in most cases sufficiently precise: Measuring the temperature of critical components determines whether the initially selected fan achieves satisfactory results. The optimum fan is then selected by changing the fan size and/or adjusting the speed. With the given temperature increase and the amount of heat to be dissipated, the required volume flow rate can be determined approximately in the curve.

The fan must deliver the determined volume flow rate despite the increase in pressure. If the device curve is unknown, the pressure increase of the device must be estimated. Depending on the component density in the device, the operating point can be estimated at 15 to 30 percent of the maximum pressure. This range is well covered by standard axial fans, without entering the unfavourable saddle range of the fan curve. If the pressure increase is due to extreme component density then the preferred choice is a tangential or radial fan whose curve has hardly any or no saddle at all.

What noise is tolerable?

The cooling of an electronic device must be included in the planning from the very beginning. It is recommendable to reduce the size of an overdimensioned cooling system after the final measurements have been made rather than subsequently improving an underdimensioned cooling system that entails considerable difficulties.

Rules for selecting a noise-optimized fan:

- Always choose the mechanically largest fan. The larger the fan the lower the speed can be to ensure the required air flow.

- Adapt the volume flow rate to the cooling capacity that is actually required by temperature control.

- The output of a fan must always correspond to the most unfavourable conditions. In normal operation, this output is hardly needed, the fan can rotate more slowly. This can be achieved by an affordable small electronic component for every DC standard fan. The speed of DC fans is controlled via the operating voltage. The lower voltage limit specified in the data sheet is necessary to ensure a reliable start-up and must be applied briefly when started. During operation the voltage can be reduced to 50 percent, 5 VDC fans require min. 3.5 VDC operating voltage after run-up.

- Choose sleeve bearing fans with extremely low speed as they develop less structure-borne noise than fans with ball bearings. SEPA EUROPE’s MagFix® technology reliably prevents the disadvantages of older models of sleeve bearing fans and can be operated in all installation positions. Axial fans and radial fans with a modern blade shape (e.g. LF40P05) develop significantly less noise with the same volume flow rate.

Horizontal or vertical ventilation?

When designing a device or a unit it is necessary to determine in which direction the air should flow and likewise the position of the fan, fan intake and air outlet. As electrical units heat the air it is advantageous to use the effects of free convection and choose the upward direction of flow. This principle applies in particular to tall units, e.g. cabinets. In many types of units however, in particular in flat designs, the energy that results from the differences in temperature is much lower than the flow energy produced by the fans. All other alternative directions of flow can be realized without having to make noticeable compromises.

Fundamentally, the fan operates at the same intersection between the fan curve and device curve irrespective of the flow direction. Attention should be paid however to fact that the suction flow of a fan is virtually linear, whereas the discharge direction is turbulent, in other words irregular and in a preferred direction (axial = axial fan). The turbulence enhances the cooling effect on the components that are aligned with the air flow. In this case, the pressure side is recommendable as the fan is not affected by the hot air discharged from the device. It suctions in the relatively cool ambient air and this increases the service life.

What is the best bearing system?

The bearings of the motor shaft are a decisive element for determining reliability. Two completely different bearing systems are used: Ball bearings or MagFix© sleeve bearings. It is actually not easy to make the correct decision. The planned use, the size and the weight of the fan rotor, environmental conditions, service life expectancy, reliability and costs must be carefully weighed up.

Ball bearings are precision components that are maintenance-free and permanently lubricated. They have the advantage that they can be used in a wide temperature range (40 °C – 85°C). They are extremely reliable and have a service life expectancy of up to 350000 h (MTBF at 40 °C). However, fans with ball bearings are highly sensitive to shock and vibration and are somewhat more expensive than sleeve bearing fans.

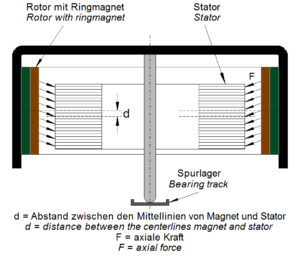

The MagFix® bearing comprises a sleeve bearing for the radial positioning and a so-called bearing track for the axial fixation at the tip of the rotor shaft. In simple terms, a force in axial direction is used by an offset of the coils to the magnet or by a magnetic track plate to secure the fixation in the bearing track. The bearing shoulders thus remain free and oil cannot migrate. The outstanding features of fans with MagFix® bearings are: low noise, high shock and vibration insensitivity and an affordable price.

What accessories do I need?

In order to meet the requirements of modern high-performance electronics different methods of mounting are available. These include, mounting rivets, fan sleeves, fixing screws, thermally conductive adhesive and double-sided heat conduction pads. All these ensure the secure mounting of fans and heat sinks.

An important accessory however, is also the finger guard. As the name implies, the most frequent application is the protection against unintentional contact. Special filter guards can also prevent the penetration of small particles or dust or can be used as a shield against electromagnetic radiation.

External finger guards are far superior to the ring-shaped slits in the metal housings as they rarely create air turbulence that in turn results in higher fan noise and a lower volume flow rate. With the use of finger guards, a protection class of IP20 to IP54 can be achieved depending on the design.