Finger guards in electrical appliances and control cabinets

There is hardly another mechanical component that has such diverse usage as a finger guard. As the name implies, the most frequent application is the protection against unintentional contact. Furthermore, special filter grille panels can also prevent the ingress of smaller particles or dust or provide a shield against electromagnetic radiation. External finger guards are clearly superior to the ring-shaped slits that perforate the metal housings as they hardly generate any swirls of air. This results in an increase in fan noise and an airflow that is too weak. Depending on their design, finger guards can achieve a protection level of IP20 to IP54. They can be adapted to the housing design and thus enhance its appearance.

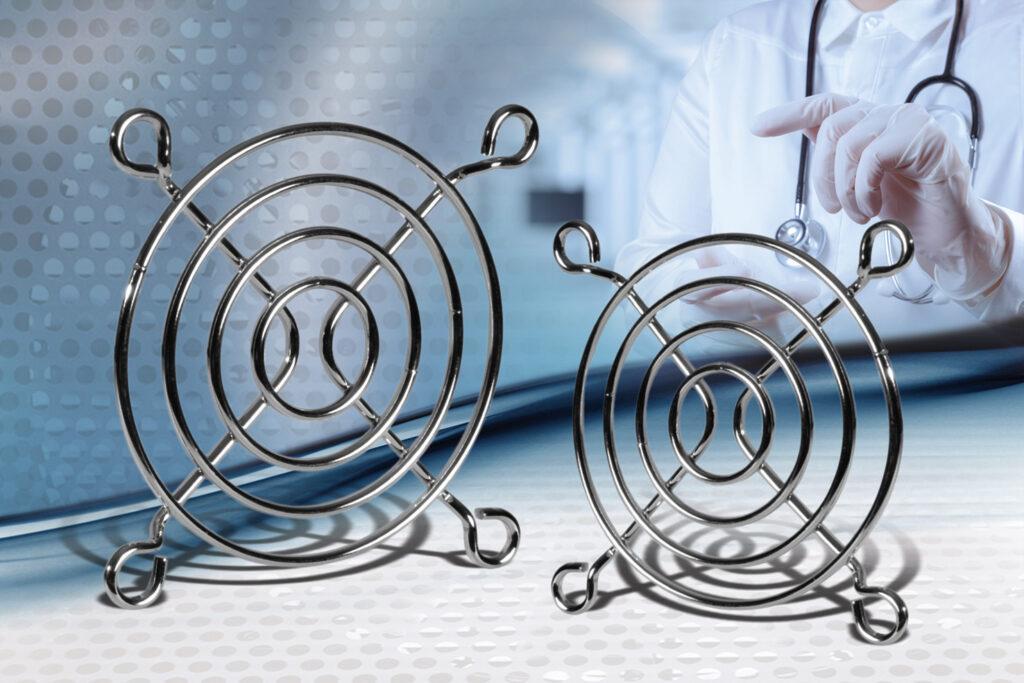

The standard finger guard

The standard finger guard Type FG has a concentric design comprising wire rings. The gap between the ring circles must be just small enough to prevent the fingers entering the fan and unintentionally coming into contact with live parts or mechanically moved parts.

The guard comprises iron wire rings that are electrically welded to 2-4 radially positioned wires. These wires usually have hooks at the end of them for attaching the guard. Corrosion is prevented by an electrochemical chrome plating. The high quality and the bonding of the chrome surface is achieved by a copper sublayer. This ensures that the guards are extremely resistant to the normal environmental conditions while simultaneously meeting the high optical demands. Thanks to the powder coating, finger guards are available in a variety of colours and can be adapted as desired to the relevant appliance

design.

The standard guards are available in the standard sizes adapted to the fan dimensions e.g. 25×25 mm to 150x170mm, however they can of course be customized with regard to both special dimensions and shapes.

Guards for products with special hygienic requirements

In the medical sector, foodstuffs industry and laboratory technology particularly high requirements must be fulfilled with regard to temperature and corrosion resistance. Stainless steel wire finger guards are available for these special applications.

The electromechanical ablation of the stainless steel guard is equivalent to a fine deburring: microscopically fine surface roughness is further reduced and edges and corners removed. The surface treatment provides an

additional significant benefit to the material properties of stainless steel. The special reworking makes it considerably more difficult for germs to remain on the surface. Furthermore, electropolished surfaces are less susceptible to corrosion.

If a wire guard is not desired, e.g. for optical reasons, a plastic finger guard Type FGK is used. In many cases it is also necessary to prevent the ingress of foreign objects and dust. For this purpose, the plastic guard is equipped with an additional cover behind which a filter mat and fine-mesh plastic guard Type LFG is located.

The cover can be removed so that the filter mat can be either replaced or cleaned. EMC shielding is achieved by inserting a 0.25 mm thin shield sheet of stainless steel Type FSB underneath the plastic guard with electrical contact to the metal housing. A special grid pattern ensures an optimum shielding effect with simultaneous negligible pressure loss.

Fan screen grid for EMC applications

An EMC fan screen grid Type FM is available if a higher EMC protection is required. It comprises a metal frame and a fine wire mesh filter and is screwed (conducting) to the metal housing using countersunk screws. This filter also prevents the ingress of small particles >0.5 mm.

Filter fan units with guard for control cabinets

Plastic guards and covers (FPF) are used to prevent the ingress of water. Protection level IP22 is achieved with the simplest form with a roof-shaped louvered grille and up to protection level IP24 with an additional cover. These parts can be supplied as an

assembly complete with fan.

Conclusion

Finger guards are extremely versatile components for protecting against contact, ingress of foreign objects and water as well as for EMC shielding. Quite remarkable is also the fact that most of the above-mentioned guard designs can be combined thus multiplying their effectiveness. They can also be mounted directly on the appliance housing. The standard sized finger guards and EMC fan screen grids are extremely cost-effective and available ex stock or in customer-specific designs.